Chemicals have been in use since ancient times, and in the modern era, they are pretty much used in everything. Clothes, food, pharmaceuticals, or anything else. But did you know mixing them in a proper amount is essential?

But why?

Former CEO of Chesapeake Energy, Aubrey McClendon once said, “Modern life would not be possible if it were not for chemicals, nor would modern natural gas production”. This is true as synthetic substances have become a major part of all sectors.

So, in this article, I’ll talk about why proper chemical mixing is critical for industrial manufacturing. If you own such a business that uses contaminants, then pay attention, as it’ll help you.

Improved Consistency And Quality

Industrial manufacturers have to meet certain standards whether it’s color, texture, or viscosity. The final product needs to be of high quality so that customers get attracted to it.

This is why they meld chemicals in a precise ratio, as it makes the merchandise appealing. If it’s not done securely, it can mess it up, and it won’t meet quality standards, which will fail when it is in the market.

Money, material, and manpower will go to waste if the goods fail to perform in the market. If the components are mixed correctly, it enhances reliability and functionality. Manufacturers often track pressure changes during blending, and Industrial Pressure Gauges help teams spot irregular readings before they affect the batch. That kind of monitoring reduces rework and keeps each production run stable.

Enhanced Product Stability

A stable item ensures safety, longevity, and performance. But to achieve it, you have to prepare the chemicals properly. An imbalanced equilibrium will cause a drop in shelf life, usability, and customer dissatisfaction.

You can get help from Visimix – Chemical mixing software or any other such program that will give you accurate measurements. This will save you time and money. Such tools also reduce human errors and provide better accuracy.

Product reliability and composition are maintained this way, which promotes higher consumer satisfaction. It also creates a positive image in the eyes of the buyer, as they are getting the best of the best.

Increased Safety

It’s no joke, but chemicals can be harmful if they aren’t mixed in the appropriate amount. This could harm the user and degrade the brand image. Not only that, but it can cause damage to your workers as they are working near it.

Strict protocols should be followed to ensure the safety of everyone because even a small mistake can be fatal. But if your brewing game is on point, it will go the other way around.

Not only your final item will be the finest, but you can rest assured about people using it. You’ll also be saving the environment, as the chemicals won’t generate heat or release hazardous gases.

DID YOU KNOW?BASF is the world’s biggest chemical production company, located in Ludwigshafen, Germany!

Reducing Waste

Minimizing waste must be your priority because off-spec batches or excess ingredients would be gotten rid of, which is going to cost you money. However, using the recommended amount will decrease material use and disposal.

Companies that deal with solvents must take a close look at their operation and look for ways to decrease wastage. They can conduct demo sessions for employees so they can learn what they can do to ensure minimal disposal.

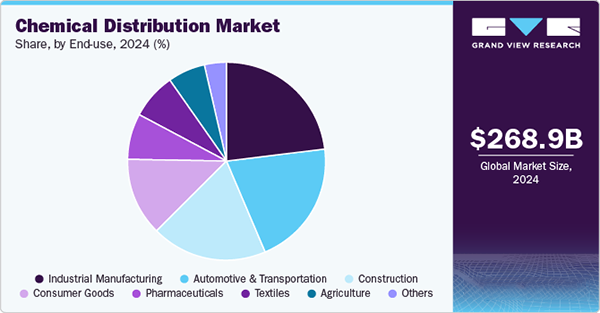

The chemical distribution market is valued at $268.9 billion in 2024. In the graph below, you can see what sectors are the major contributors.

Preventing Equipment Damage

Equipments are one of the major investments that cost a lot of money, so imagine it getting damaged, and you’ll have to get it fixed or replaced. Sounds heavy on the pocket, right?

Improper chemical blends can damage your machines, causing corrosion or mechanical stress. You should follow the rules and guidelines and do things in accurate batches to avoid this.

Keep them in condition by monitoring and regular maintenance to ensure that they operate smoothly and if there are any issues, they can be resolved quickly.

Regulatory Compliance

Chemicals need to be handled with care and some strict rules and regulations need to be followed. Companies should make improvements in their compounding process to comply with local or state laws.

Proper compound mixing is critical if you want to create great goods, but the safety of consumers and people working around it is also your priority. While using chemicals is not ideal these days, it’s a must for product quality.